How to Inspect and Diagnose Roller Pump Damage

How to Inspect and Diagnose Roller Pump Damage

Roller Pumps are one of the most common pump types that we sell at Sprayer Depot. They are a great pump for a number of applications. However, like all spray equipment, they experience wear and tear that can lead to breakdowns. We'll cover 5 areas of the roller pumps that are susceptible to wear, and how to determine if you need a repair kit or a full replacement pump. If you need to shop for a new pump, here are 3 steps to selecting the right roller pump.

5 Areas of Roller Pump Wear

When you’re looking for signs of wear, here are five areas to start. We’ll be using a Hypro roller pump as a point of reference throughout, but the main points apply to any make or model.

Housing Wear: The first place to look for wear is the housing. Make sure it’s in good condition, checking on both the inside diameter and the back face. Check 1/16” from the edge and look for a lip as an indicator of excessive wear.

Cover: When looking at the cover, keep an eye in the roller area in particular.

Rotor: When you’re looking at the rotor for signs of wear, you should look at its size. An undersized rotor, or one with worn roller slots, is a sign of excessive wear. To determine if it's undersized, you’ll want to measure the thickness of the rotor, which on a Hypro 7500 series roller pump should be 1.4995" at its smallest.

Rollers: Much like the rotor, undersized or swollen rotors in both length and diameter are not good. Measure the thickness and make sure it’s no smaller than 1.4995". Any smaller and it may be worn out and need to be replaced. Always make sure to replace rollers as a set, not just one at a time.

Shaft: Check the drive end of the shaft for wear, as well as in the seal area, for signs of excessive wear include pitting or grooves. If it’s worn or pitted, the shaft needs to be replaced to ensure proper sealing.

Repair or Replace?

A good rule of thumb for determining if you should try to repair the pump or just replace it, is to consider the cost of the repair kit(s) needed. If the repair kits cost more than half the price of a new roller pump, it will be more economical to replace the pump.

Repairing a Roller Pump

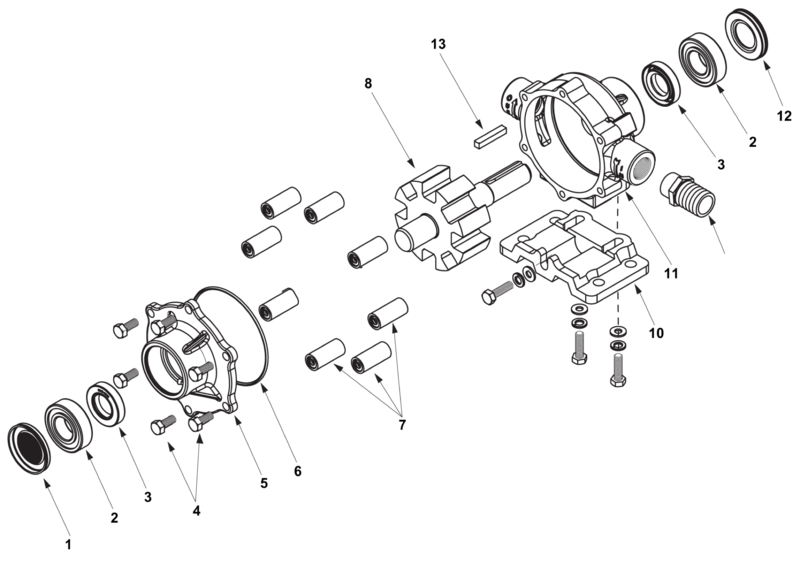

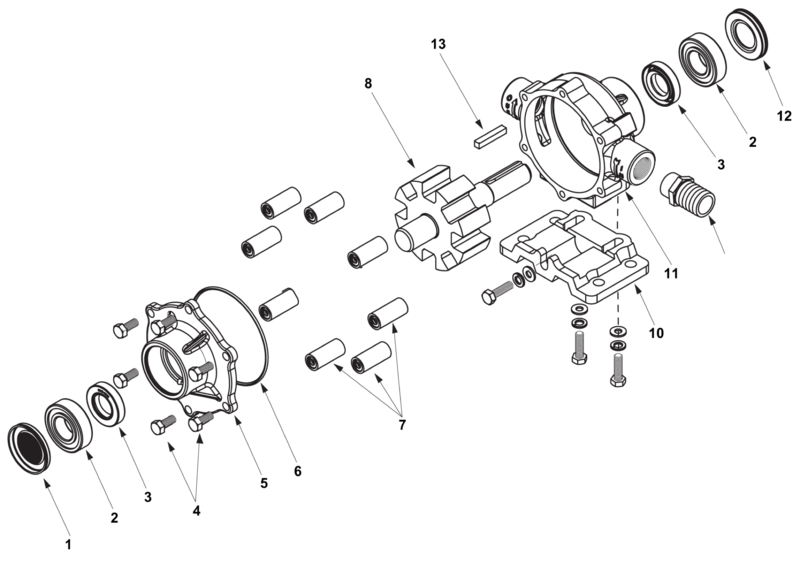

After evaluating the areas listed above, decide if the pump is repairable. If it’s just a repair, grab a repair kit and the following tools: socket, hammer, cradle (to support the housing), file and a measuring tool, etc. Then follow these steps to disassemble the pump, or watch the video tutorial included below:

- Remove the adapter from the pump shaft.

- File off any burrs on the pump shaft.

- With a screwdriver, pry bearing covers off the endplate and body.

- Remove the endplate bolts.

- Support the pump at its ports in a support fixture with the endplate down. Place it on a press bed. Center the press on the pump shaft and apply pressure to press the pump apart. Note that the shaft and rotor will remain with the endplate.

- Remove the rollers and endplate o-ring seal.

- To disassemble the rotor from the shaft, place the endplate in the support fixture with the rotor down. Center the 3/8" bolt on the pump shaft and apply pressure to press the shaft out of the bearing.

- With the endplate in the support fixture and the front of the endplate facing down, center the bearing support tool and slowly press the bearing out of the casting. Repeat the procedure to remove the bearing from the pump body.

- Punch the seals out of the endplate and body with screwdriver and hammer. Then discard the seals – seals can’t be removed without damaging them so you’ll need to replace them regardless.

Once the necessary repairs have been made and the pump is clean of debris, reassemble the pump. Note that when you’re tightening the bolts, tighten them in a crisscross pattern. Then check to see if the rotor is centered in the pump case by turning the pump shaft by hand. If the pump turns hard, place a wooden dowel against the end of the shaft, centering it on the shaft, not the bearing. Tap lightly with a hammer. Try turning the shaft again and if it turns more easily you should be good. If this doesn’t do the trick, repeat the steps and tap the other end of the shaft. These minor adjustments will ultimately align the shaft, but if that doesn't work, try cleaning the pump - it's possible a piece of debris is caught inside.

Now that your roller pump is back in action, take care to ensure it lasts longer and performs better by maintaining it regularly. After each use, make sure to flush the pump with a neutralizing solution that's meant for the liquid you just pumped. Follow with a clean water rinse. This is especially important for corrosive chemicals. It is good practice to clean the pump after each use to prevent deposits from forming and damaging the pump.

New Product Line: Kings Steel Sprayers

Kings Sprayers are now Available with a Rugged Steel Frame

Kings Steel Sprayers are built on steel frames, designed to stand up to harsh conditions and use, while offering cost savings over the original aluminum frame Kings Sprayers. They are an ideal entry-level sprayer for those just entering the spraying industry, or those who spray more infrequently.

Read More About Kings Steel Sprayers

Shop Kings Steel Sprayers

Sprayer Depot is committed to serving you!

- Order at sprayerdepot.com, call 1-800-228-0905, or email sales@sprayerdepot.com

- Online Chat available at sprayerdepot.com

- Have a question? Email info@sprayerdepot.com, or call our knowledgable Customer Service Technicians at 1-800-228-0905

- Orders over $100 enjoy FREE Shipping (some exclusions apply), and are shipped out the same day when ordered by 5pm (ET)

- Sprayers ship for a flat rate to the 48 contiguous states

- QuickShip Kings Sprayers are ready to ship same day when ordered by 12 noon (ET)

- Central Florida Showroom open Monday through Friday from 8am to 5pm at 7800 N. Orange Blossom Trail, Orlando

- Orders are shipped from distribution centers in Orlando, Florida and Salt Lake City, Utah for fast shipping

- Want to hear what customers say about Sprayer Depot? Visit our Customer Reviews page.

Sprayer Depot specializes in spray equipment, parts and accessories for commercial use. Agriculture, horticulture, lawn & landscaping, and pest control industries, as well as theme parks/resorts/hotels, and golf & recreational facilities shop at Sprayer Depot. Kings Sprayers are proudly made in America at the Sprayer Depot headquarters in Orlando, Florida.

We appreciate your business, and look forward to assisting you again in the near future. Happy Spraying!

How to Inspect and Diagnose Roller Pump Damage

How to Inspect and Diagnose Roller Pump Damage